X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 9 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 21,284 times.

Learn more...

Hydraulic die forming is somewhat similar to Masonite die forming. In both, sheet metal is sunk or pressed into a die. The sheet metal takes the form of the design cut into the die. Hydraulic die forming is quicker and lends itself more to duplicating formed-art or other production.

Steps

-

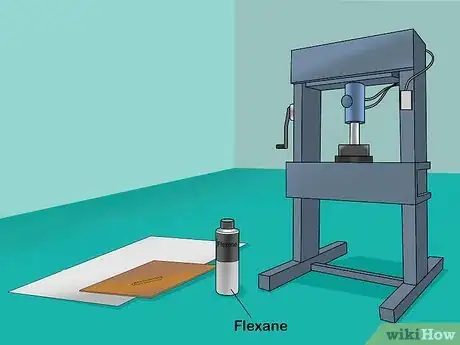

1Gather all material needed, including a hydraulic press.

-

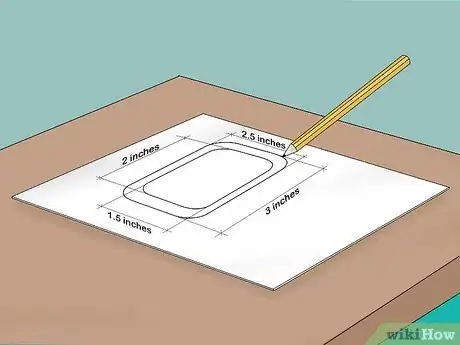

2Draw design on craft paper. The design chosen for die forming should only be an outline of a form nothing intricate. Make sure the edge of the material to be cut is approximately 1/2" to 1" away from the edges of the design.

- Example: if the design chosen is 2 inches (5.1 cm) in diameter, then the material to be cut should be at least 3 inches (7.6 cm) square.

Advertisement -

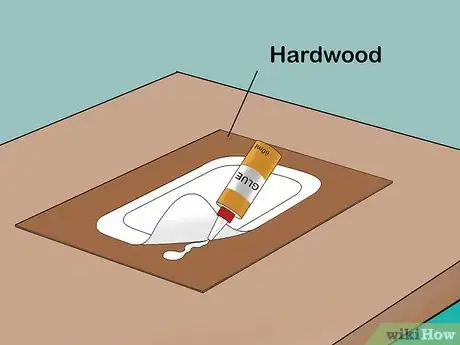

3Glue craft paper with design drawn on it with design side up and on center on material to be cut.

-

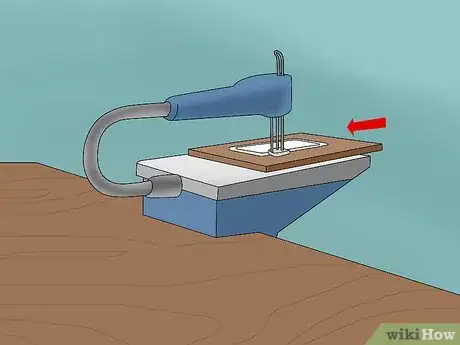

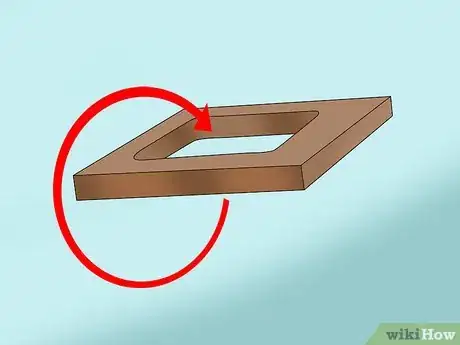

4Wait for glue to dry then drill a hole next to the inside edge of the design

-

5Use the scroll saw or Jigsaw to cut out perimeter of design. This is what creates the void that the sheet metal will be pressed into.

-

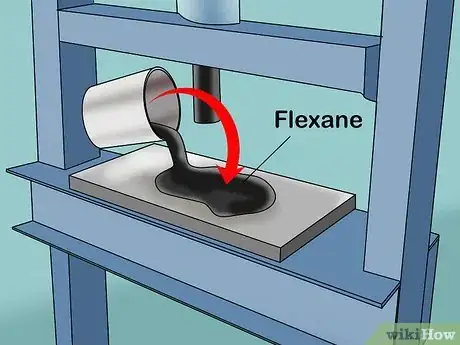

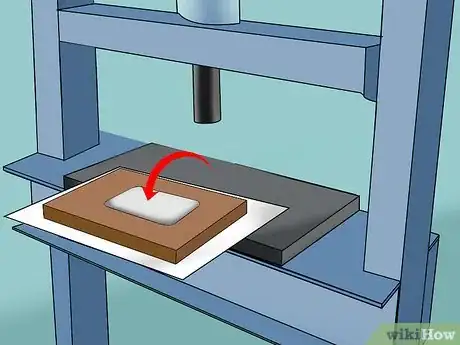

6Place the pad of Flexane onto the bottom platen of the hydraulic press.

-

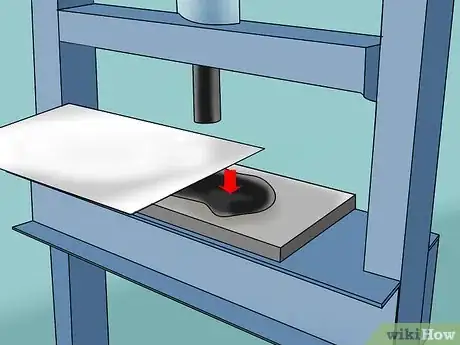

7Place sheet metal to be used on flexane.

-

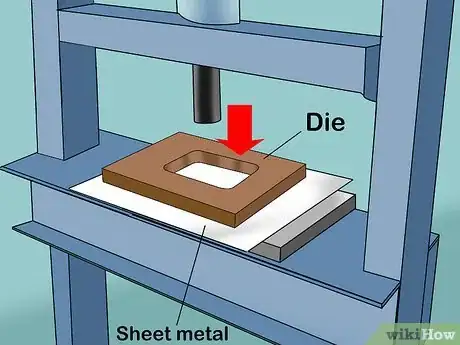

8Place die in position desired on sheet metal.

-

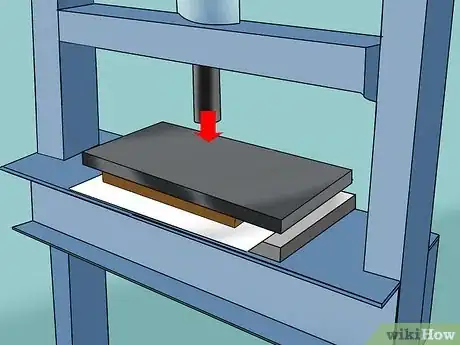

9Pump arm of hydraulic jack to advance lower platen (which rests on the head screw of the jack) to press the die and metal padded with flexane against upper platen as far as it will advance.

- This action will force the flexane (a rubber or urethane compound) to push the sheet metal into the die.

-

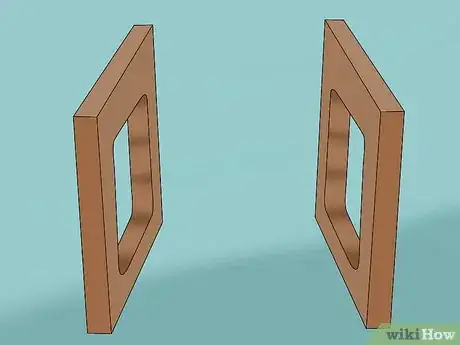

10If two halves are desired, make sure the right half of the die is a mirror image of the left half.

-

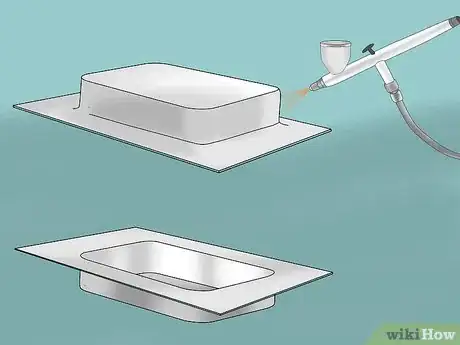

11Lower the jack and remove the die with the form that was just pressed.

-

12Flip the die over, to use it as the mirror image, onto another piece of sheet metal which is sitting on the flexane and press the other half.

-

13Finish the metal art form(s) as desired, such as lacquering or painting.

Advertisement

Community Q&A

-

QuestionCan a 16 gauge iron sheet be formed in this way?

Community AnswerWith a 20 ton press it may leave an impression in the steel, but it will not be very deep. It will with more hydraulic tonnage.

Community AnswerWith a 20 ton press it may leave an impression in the steel, but it will not be very deep. It will with more hydraulic tonnage.

Advertisement

Things You'll Need

- Hard material like plastic, Masonite, hardwood (for die)

- 20 ton hydraulic bottle jack

- Shop press or Hydraulic press

- Craft paper

- Jigsaw or scroll saw

- Drill press

- Thick pad of 8" square Flexane (urethane compound)

References

- Based on blogger.com/formingart by Rparus, metal-artist (who started this article)

About This Article

Advertisement