wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 9 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 20,979 times.

Learn more...

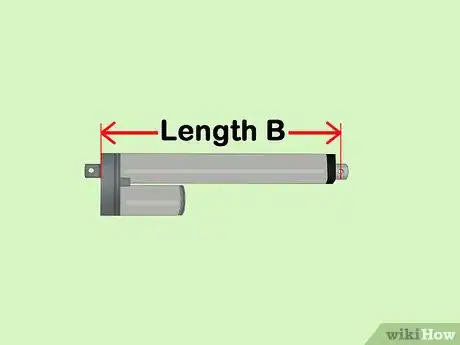

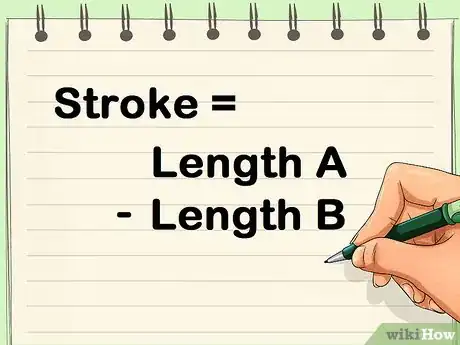

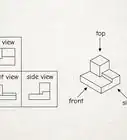

Stroke is the distance travelled by an actuator in motion. This is a measurement of the capability of a linear actuator. The stroke will help you determine whether the actuator will work in tandem with your application. The measurement of stroke is imperative to the efficient and safe combination and usage of the actuator and mechanism it is connected to. Stroke helps determine key factors such as the weight capacity of the actuator, how much time will it take, the speed of the motion, and the force that can be generated. When purchasing an actuator, it is important to know the measurement of stroke to understand its capabilities.

Steps

Detaching the Actuator

Re-attaching the Actuator

Measuring the Second Length

-

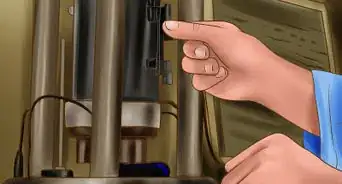

1Let the application actuate to its full capacity. Ensure that the actuator produces its motion entirely.

-

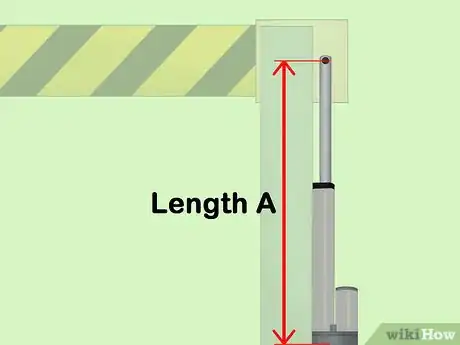

2Measure the length of the actuator in its extended state. Measure from the end of the actuator to the centre of the pin or bolt hole. Make sure that the exact spot of measurement is the same as the spot of your earlier measurement. Make a note of this length and call it "Length A".

Warnings

- Only experienced professionals should open a device and handle its components⧼thumbs_response⧽

- Before disconnecting the actuator, make sure the power supply is switched off⧼thumbs_response⧽

- All components of the device should be handled with care⧼thumbs_response⧽

- Handle all equipment with the right safety gear.⧼thumbs_response⧽