X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, volunteer authors worked to edit and improve it over time.

This article has been viewed 26,041 times.

Learn more...

Wood turning specialists have been around for as long as fine woodworking has existed. They turn wood into legs, columns and spindles to incorporate into their furniture. This part of woodworking has become even more diverse with the advent of modern lathes and turning tools.

Steps

-

1Purchase a wood lathe. You will also need accompanying turning tools.

- Lathes and basic turning tools are found in woodworker supply stores. The basic tools include a parting tool, gouge, skewed chisel and scraper.

-

2Set up the lathe. Use a space with good lighting and in an area that makes for easy cleanup for the wood chips and dust.Advertisement

-

3Sketch out the shape you want to achieve on a sheet of paper. Keep the design within the limits of the wood blank and capacity of the lathe.

-

4Mark the center points. Begin turning by finding the center of the wood stock on each end.

- Draw a line from one corner to opposite corner on square or rectangular stock. The point where the lines intersect will be the center.

- On round stock, use a self-centering tool and follow manufacturer's instructions.

- Mount the wood by centering it onto the headstock of the lathe spur.

-

5Slide the tailstock center spur up to the center of the other end of the wood. Next, lock it down.

-

6Turn the handle on the tailstock center. This drives the wood blank into the spurn of the headstock, securing it between the centers.

-

7Set the tool rest to an approximate center of the work piece. Get it as close as possible, without it hitting the work piece when it is turning.

-

8Start the lathe on slow speed. Use a gouge to rough out or round off the piece to the basic shape you need.

-

9Position the large gouge, tip turned up, onto the tool rest. Place the end of the handle against your hip.

- Slowly lower the tip until it engages the wood and begins to chatter.

- Work the gouge back and forth along the wood surface and against the tool rest until the chattering stops and the stock is round.

- Increase the speed of the lathe and use the small gouge to finish roughing out the shape.

-

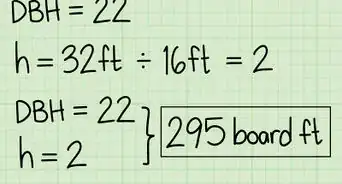

10Use the parting tool with a pair of outside calipers. Use these tools to set the depth of cuts you will need.

- Hold the narrow end of the tip against the tool rest and push it straight into the work piece. Check the calipers frequently until you achieve the depth you need.

-

11Set the skewed chisel at an angle onto the tool rest.

- Refine the shape you want by moving the chisel back and forth over the tool rest and surface of the wood blank.

- Trial and error will help to determine the most efficient angle needed to hold the skewed end of the chisel to the face of the work.

- Employ the rounded flat end of the scraper chisel, supported against the tool rest, to run over the surface, smoothing out any tool marks.

-

12Sand the piece while it is still mounted. Ensure that the piece is turning at a slow speed. Begin with 180 grit and finish with 440 grit sandpaper.

-

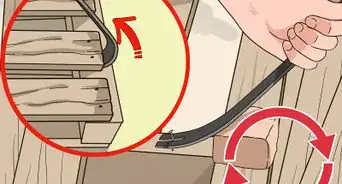

13Cut the end of the work that is attached to the headstock and tailstock loose with the parting tool. This will sever it from the finish piece while the work is still slowly turning.

- Continue supporting the back side of the piece with your gloved hand. The work piece will fall off into your hand.

- You can remove the piece from the other end by cutting it off with a fine-toothed hand saw. Set the tool rest to an approximate center of the work piece, and as close as possible, without it hitting the work piece when it is turning.

Advertisement

Community Q&A

-

QuestionWhy do turners use a pressurized tank when using epoxy?

Teachme2Community AnswerThe pressure helps shrink the air bubbles in the resin so they can’t be seen in the piece.

Teachme2Community AnswerThe pressure helps shrink the air bubbles in the resin so they can’t be seen in the piece.

Advertisement

Warnings

- Always use safety goggles and or a full face shield to protect yourself from flying chips. Also use a dust mask, as some of the dust and chips from a number of exotic woods can be toxic.⧼thumbs_response⧽

Advertisement

Things You'll Need

- Lathe

- Turning tools set consisting of parting, large and small gouge, skewed and scraper chisels

- Wood blanks

- Different grits of sandpaper from 180 to 440 grit

- Straight edge

- Calipers

- Tape measure

- Self-centering tool

References

About This Article

Advertisement