X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 11 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 60,024 times.

Learn more...

Few tools can make a job of cutting metal tubing or other stock easier than a bandsaw. On those occasions when the stock cannot be brought to the machine, portable bandsaws offer the option of taking the machine to the work. Here are some basic steps for using this versatile and portable power tool.

Steps

-

1Rent or buy the portable bandsaw best suited for your needs. Commercial or Industrial Grade tools are expensive and often somewhat heavier than handyman or homeowner's grades, and most portable bandsaws fall in the former category. Here are some options you may find on portable bandsaws:

- Capacity. Since the stock or material you are cutting must fit in the throat of the machine, choosing one with sufficient capacity is essential. Large capacity portable bandsaws can cut pipe or angle stock up to about 6 inches (15.2 cm), whereas standard machines are limited to about 4 inches (10.2 cm) of diameter or width.

- Power source. If you are working in the field where electrical cords are not practical, you may choose to purchase a battery powered saw. These, however, are more expensive than the typical A.C. voltage saws, and have limited cutting times between battery recharging.

- Brand choice. Most name-brands offer similar features and torque, and use a common blade length. Common brands include Porter Cable, Milwaukee, Ridgid, and DeWalt, and are available at builder's supply centers and tool retailers. Discount retailers offer off-brand tools which serve the same purpose, but may be of lower quality than the previous brands, at much lower prices. Be aware that with power tools, as with many consumer products, you will probably get what you pay for.

-

2Familiarize yourself with the tool. Portable bandsaws use a trigger switch similar to drills and circular saws, but usually are equipped with a separate speed selector so the sawblade moves at a speed suitable for the material you are cutting.Advertisement

-

3Use the two handles, one located on each end of the saw to hold the tool while it is operated. This will allow you to guide the tool, while maintaining complete control of it. Other notable components your should be familiar with are these:

- Tracking adjustment. This feature allows you to adjust the path the bandsaw's blade travels as it revolves around the rear drive pulley and the forward idler pulley. Because the front pulley floats on a spring tension hub assembly, it must be adjusted so the alignment cause the blade to travel positioned correctly on these two pulleys.

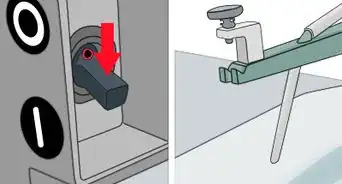

- Tension release handle. This handle, located on the forward end of the saw, is released to allow the operator to quickly and easily change the bandsaw blade if it becomes dull or is not suitable for the task at hand.

- Guide rollers. These roller bearing assemblies support the blade as it is engaged in cutting your material so it doesn't deflect or bind. Because the bandsaw blade is made of a thin, flexible metal, these rollers must rotate freely and be positioned correctly to prevent the blade from binding or warping during the cut.

- Cutting shoe. This is a flat, notched metal guide which will support the saw to offset the drag of the blades teeth as they cut the stock. This helps to insure the metal being sawn will not be dragged into the rear drive pulley while you are cutting.

-

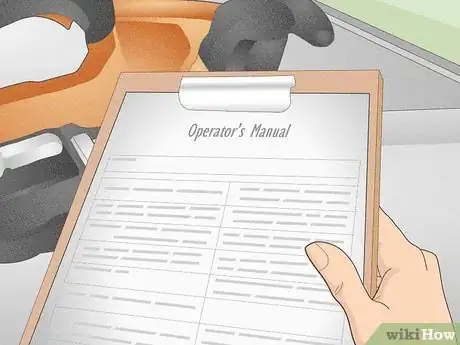

4Read the operator's manual and become familiar with unique characteristics of your choice of saws, and especially the safety recommendations from the manufacturer. Bandsaws operate with an exposed blade capable of cutting through almost any common metal from soft copper to cast iron and steel, and will cut fingers with no discretion. This is one reason why the operator should keep both hands on the provided handles (located on the back of the saw, away from the blade).

-

5Dress appropriately for using this tool. Safety glasses and gloves are very important, but also keep in mind that loose jewelry or clothing can easily get caught in the moving blade.

-

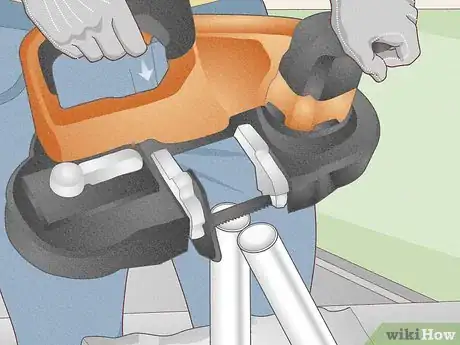

6Support loose material when cutting. Using a vice or having a helper to hold a round pipe or bar will prevent it from spinning in response to the blade biting into it during a cut. Metal which bends during the cut can bind the blade causing the operator to lose control of his saw, and heavy items can drop on the operator's feet when they fall free.

-

7Mark the stock you are cutting at the correct angle for your needs. Mark pipe around the diameter so the finished cut will be true.

-

8Place the sawblade against the stock to be cut, making sure the blade is parallel to the cut line you have marked, and perpendicular to the stock (if the cut is to be square, or 90 degrees). Keep the shoe of the saw firmly against the stock.

-

9Start the saw by squeezing the trigger and allow the saw to cut its way through the stock you are cutting. Do not force the saw or apply excessive pressure, as the saw's teeth are able to remove only a certain amount of material with each pass. Rocking the saw when cutting very thick, solid pieces of stock may allow the metal chips to clear the saw's kerf, but usually, holding the saw steady in relation to the cut is the best method.

-

10Watch the blade to make sure it is aligned with your cut mark, and slow the cut when you are nearly through the stock so you can anticipate the blade binding if the material flexes or bends suddenly. Check the free end of the stock to make sure there is nothing in the way of it when it drops off.

-

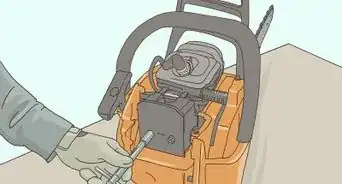

11Release the trigger and allow the blade to quit moving before setting the saw down after the cut is complete. Set the saw on a clean, level surface when the cut is finished, to insure it does not fall and become damaged, or get dirt or debris in the pulley assemblies.

Advertisement

Warnings

- Always unplug the saw when changing or replacing the blade.⧼thumbs_response⧽

- If you force the blade into the material, you stand a chance of breaking the blade. When this happens, the blade becomes a projectile and will kill or maim whoever is in the way.⧼thumbs_response⧽

- Portable bandsaws operate with an open, or unguarded blade capable of cutting almost anything that engages it when it is moving.⧼thumbs_response⧽

- Heavy steel or other materials can cause damage to floors, and serious injury when they fall loose after the cut is completed.⧼thumbs_response⧽

Advertisement

Things You'll Need

- Portable bandsaw with suitable blades.

- Power cord/power source.

- Safety equipment.

About This Article

Advertisement